Description

Product Sheet (EN): Download

Product Sheet (CN): Download

CrosserTFF™

Crosser Tangential Flow Filtration (TFF) System

GMP qualification services and 24CFR11 compliant software add-ons are available upon request.

System Highlights

- Personalized manufacturing ready

- High dynamic range: 2mL to 500L UF/DF

- Small factory footprint: 45 cm2

- Pressure control: ±0.05 psi, latency: 2 min

- GMP ready, clinically proven

- 100% single-use flow path

System Overview

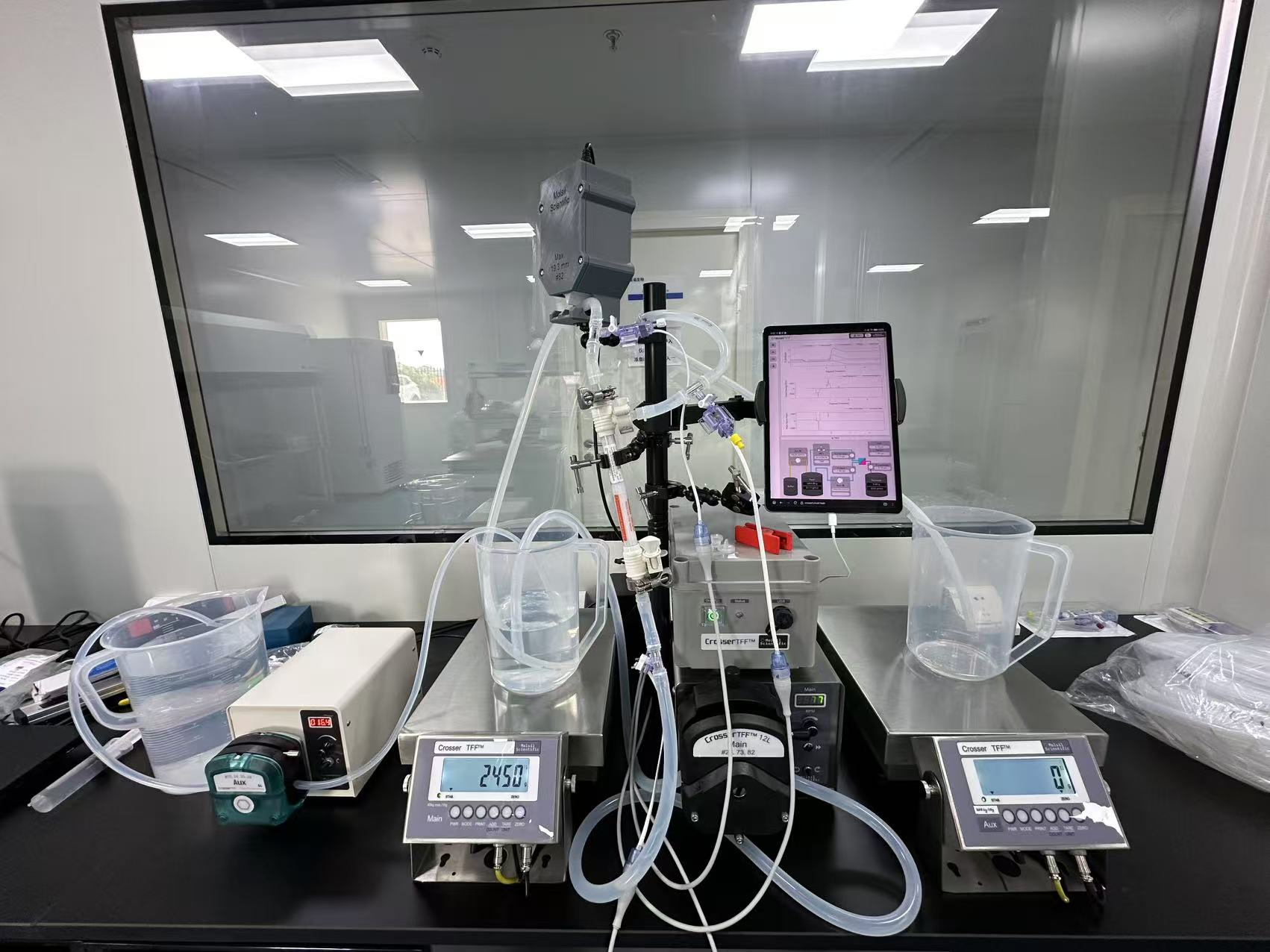

All software, hardware, and automatic backpressure control valves were developed in-house and offer industry-leading control precision and latency. The 100% disposable flow path is compatible with hollow fiber, cassette filters, and single-use pressure sensors from multiple suppliers.

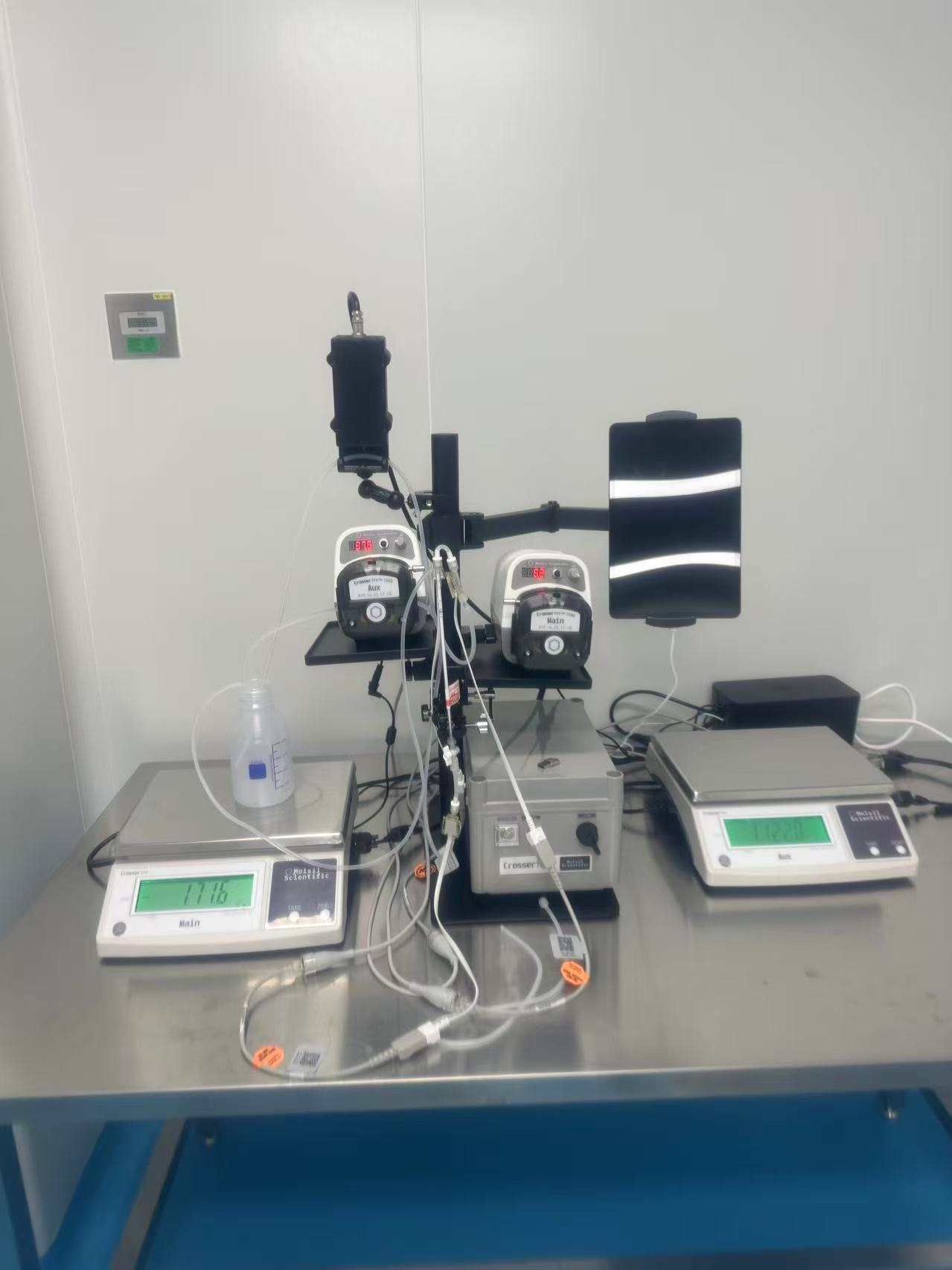

System Components

The main system components are shown in (Figure 1). The core system consists of up to two peristaltic pumps each paired with a digital scale. Three ports are available for monitoring the feed, retentate, and permeate pressures using single-use pressure sensors. The digital scales can be configured with the following modules:

| UF/DF Scale | Max. weight | Accuracy |

| 2 mL ~ 3 L | 3kg | ±0.01g |

| 50 mL ~ 5 L | 5kg | ±0.01g |

| 300 mL ~ 30 L | 30kg | ±0.1g |

| 600 mL ~ 60 L | 60kg | ±1g |

| 2 L ~ 200 L | 200kg | ±5g |

| 5 L ~ 500 L | 500kg | ±50g |

The peristaltic pumps can be configured with the following modules and tubing sizes:

| Pump | Tube | ID

(mm) |

Flowrate (mL/min) |

| CRP330 | #13 | 0.8 | 2.5 ~ 24.6 (±15%) |

| CRP330 | #14 | 1.6 | 5.1 ~ 51.2 (±15%) |

| CRP330 | #19 | 2.4 | 10.4 ~ 104.2 (±15%) |

| CRP330 | #16 | 3.2 | 17.6 ~ 176.4 (±15%) |

| CRP330 | #40 | 4 | 28.8 ~ 287.8 (±15%) |

| CRP330 | #25 | 4.8 | 33.2 ~ 332.4 (±15%) |

| CRP1500 | #19 | 2.4 | 21 ~ 210 (±15%) |

| CRP1500 | #16 | 3.2 | 37 ~ 370 (±15%) |

| CRP1500 | #40 | 4 | 50 ~ 500 (±15%) |

| CRP1500 | #25 | 4.8 | 71 ~ 710 (±15%) |

| CRP1500 | #17 | 6.4 | 120 ~ 1200 (±15%) |

| CRP1500 | #18 | 7.9 | 155 ~ 1550 (±15%) |

| CRP2400 | #19 | 2.4 | 32 ~ 320 (±15%) |

| CRP2400 | #16 | 3.2 | 55 ~ 550 (±15%) |

| CRP2400 | #25 | 4.8 | 110 ~ 1100 (±15%) |

| CRP2400 | #17 | 6.4 | 190 ~ 1900 (±15%) |

| CRP2400 | #18 | 7.9 | 240 ~ 2400 (±15%) |

| CRP6000 | #15 | 4.8 | 200 ~ 2000 (±15%) |

| CRP6000 | #24 | 6.4 | 300 ~ 3000 (±15%) |

| CRP6000 | #35 | 7.9 | 500 ~ 5000 (±15%) |

| CRP6000 | #36 | 9.6 | 600 ~ 6000 (±15%) |

| CRP13L | #26 | 6.4 | 0.4L ~ 4.3L (±15%) |

| CRP13L | #73 | 9.7 | 0.8L ~ 8.0L (±15%) |

| CRP13L | #82 | 12.7 | 1.3L ~ 13.0L (±15%) |

Optional Components

| Component | Specification |

| Single-use pressure sensor (RJ11, Utah) | 0 ~ 25 psi |

| Pressure sensor flow cell extension adapter | ID 0.8 ~ 12.7 mm |

| 24CFR11 compliance | Software Add-on |

| Installation and Operational Qualification (IQ/OQ) | Service + Documents |

Software

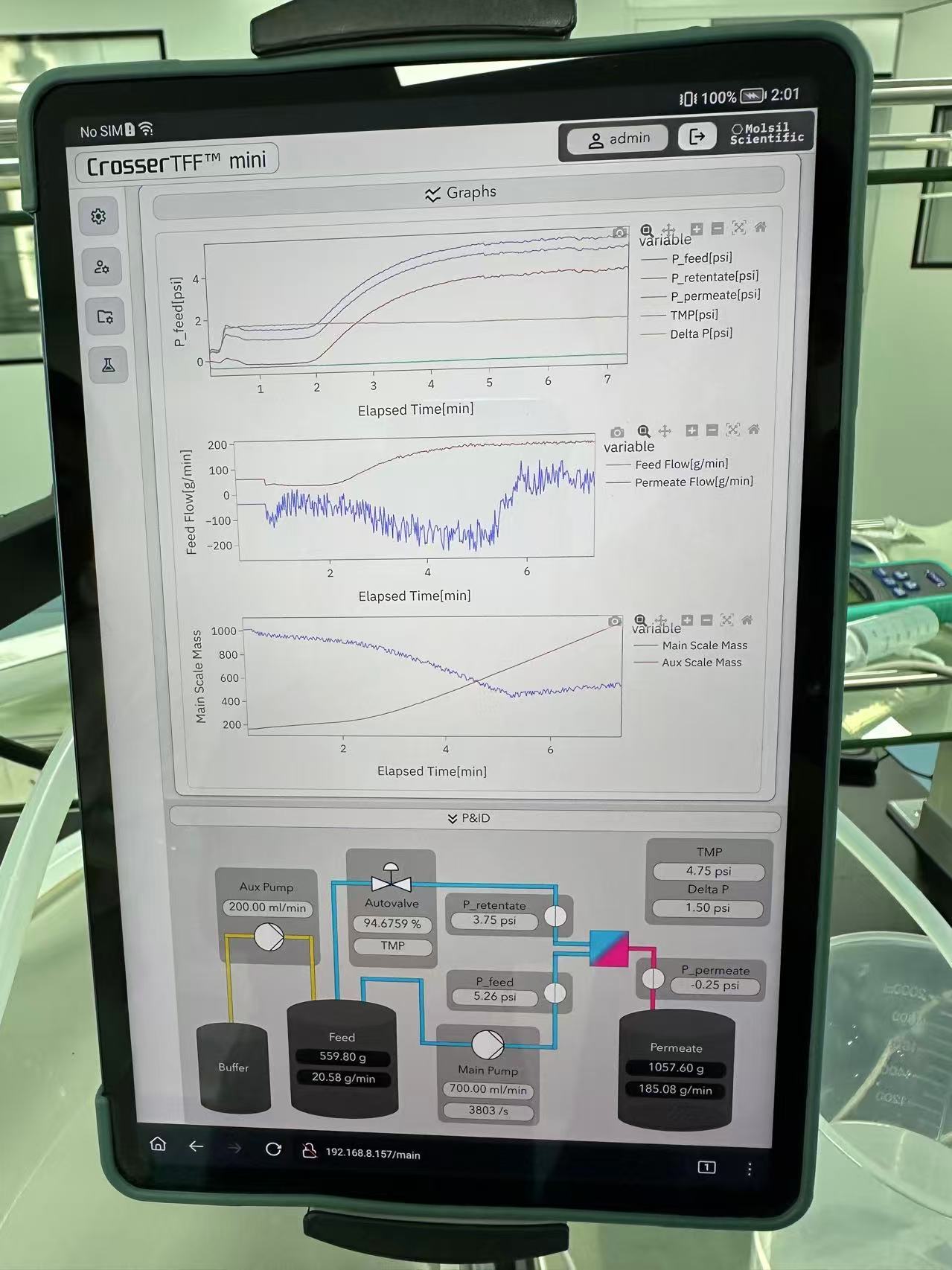

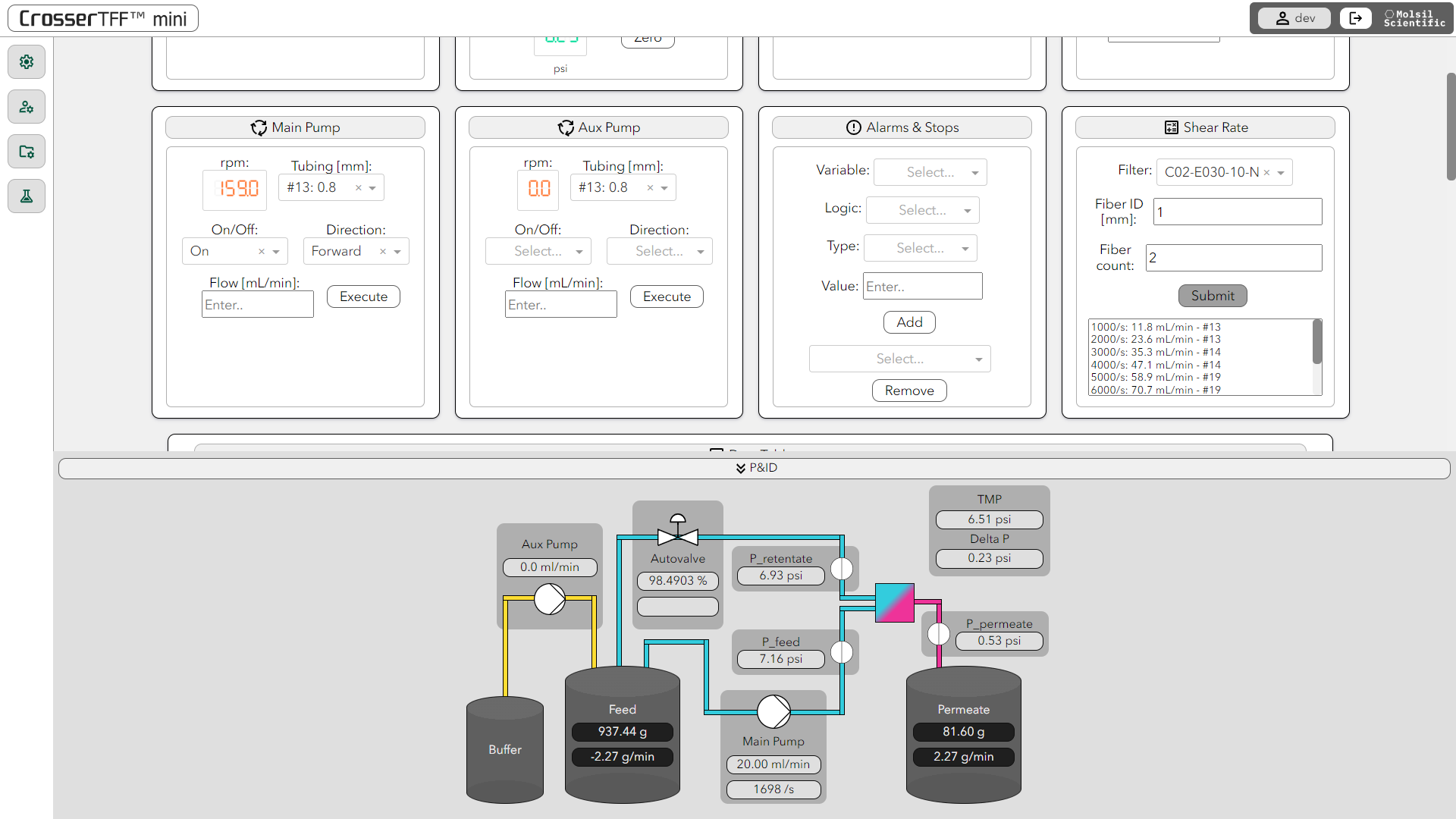

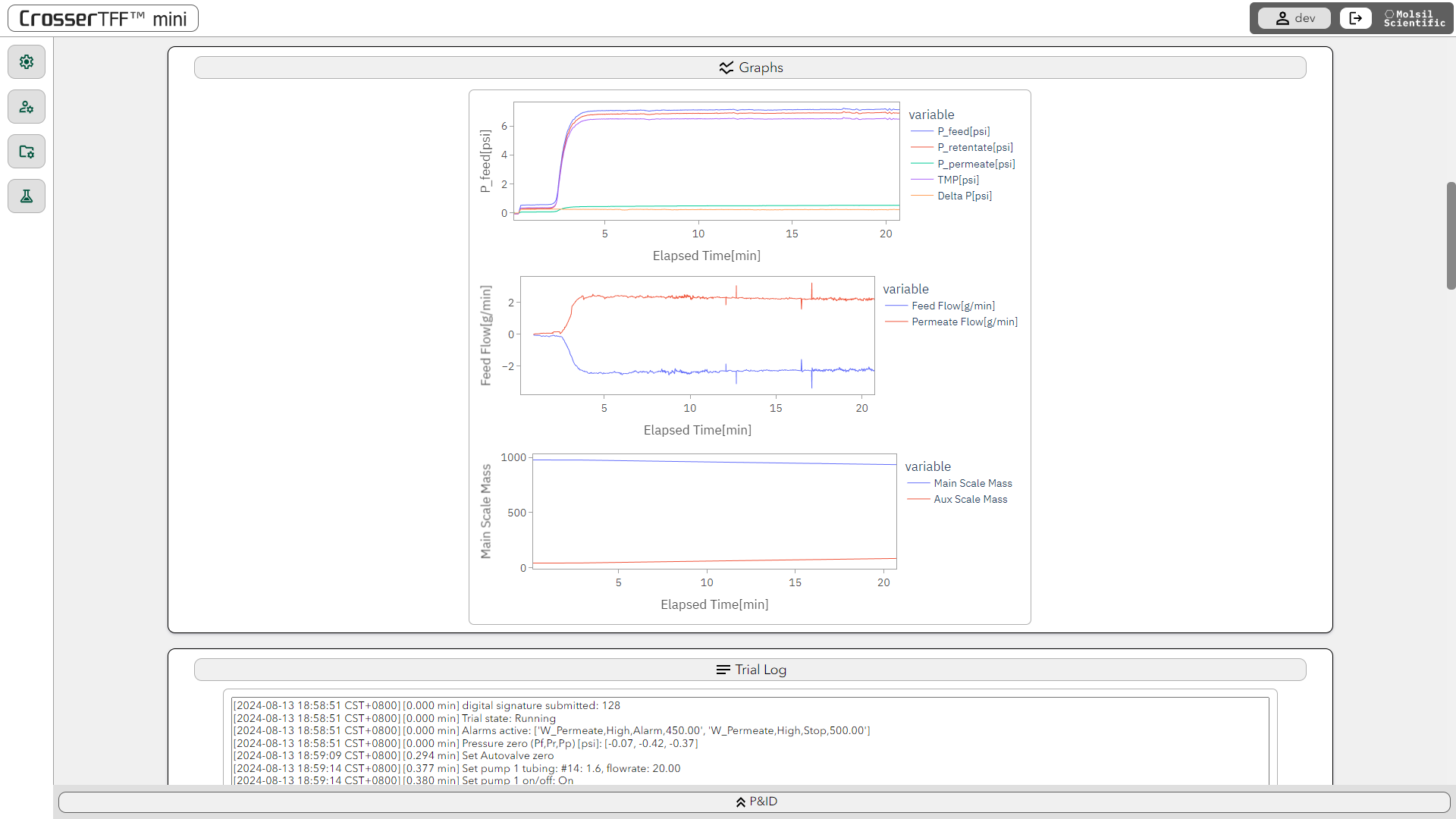

The Alker control software contains a user-friendly GUI dashboard that can be used with minimal training. The software package is optionally available with 24 CFR Part 11 electronic records compliance for GMP readiness.

Software features

| Feature | Description |

| P&ID interface | · Live piping & instrumentation diagram (P&ID) dashboard |

| Pressure control | · Automatic control of either transmembrane pressure (TMP) or retentate pressure |

| Shear rate | · Shear rate calculation for hollow fiber filters |

| Alarms and Stops | · Automatic detection of low or high levels of pressures and solution weights |

| Data backup | · Manual USB transfer

· Automatic FTP connection |

| Project folders | · Data and recipes organized and separated by project |

| User accounts | · Admin role: user and project management

· Poweruser role: project management · User role: operation only · Auditor role: read only |

| Access security | · Password rule setting

· Session timeout lock · Unauthorized login protection |

| Logging | · Audit trail log

· System log |

System Specifications

Core system

| Size | Various |

| Weight | 30 kg |

| Software | Crosser control software |

| Networking | Ethernet (or WiFi) |

| Power consumption | <500W |

| Maximum flowrates | 2.5 mL/min – 13 L/min |

| Minimum pump speed | 0.1 rpm |

| Maximum scale weights | 3 – 500 kg |

| Operating conditions | 4 – 35 °C, 20 – 80% humidity |

| Noise | < 66dB |

Ordering Information

Parts list

| Crosser control software | 20000 |

| 24 CFR part 11 software add-on | 20001 |

| Tablet computer | 20002 |

| Control box | 20100 |

| Pump aviation connector cable | 20110 |

| Pump, CRP330 | 20111 |

| Pump, CRP1500 | 20112 |

| Pump, CRP2400 | 20113 |

| Pump, CRP6000 | 20114 |

| Pump, CRP13L | 20115 |

| Digital scale cable | 20120 |

| Digital scale, 3kg | 20121 |

| Digital scale, 5kg | 20122 |

| Digital scale, 30kg | 20123 |

| Digital scale, 60kg | 20124 |

| Digital scale, 200kg | 20125 |

| Digital scale, 500kg | 20126 |

| Single-use pressure sensor | 20130 |

| Single-use pressure sensor adapter | 20131 |

| Disposable solution bag | 20140 |

| Disposable solution bottle with inserts | 20141 |

| Disposable flow-path tubing set | 20142 |

| Disposable tubing connector kit | 20143 |

| Automatic backpressure control valve | 20150 |

| Stand | 20160 |

| IQOQ service package | 20170 |

| Operational training package | 20171 |

Contact Information

Molsil Scientific

Union City, CA

Website: www.molsil.com

Email: mol-sil@outlook.com

Min Zhu –

Excellent precision, All single use components. Low cost consumable. Perfect for PCV.